Barite

Barite is a mineral made of barium and sulfate, technically known as barium sulfate (BaSO₄). One of the most significant industrial minerals, it is well known for having a high specific gravity that makes it an essential part of many different applications. The Greek word “barys,” which means “heavy,” is where the name “barite” comes from, indicating the stone’s considerable weight in relation to other non-metallic minerals.

2. Composition and Structure of Barite

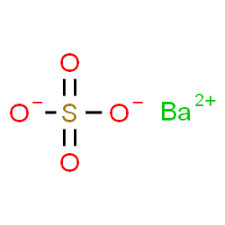

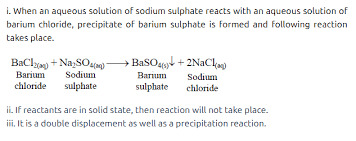

Barium (Ba) and sulfate (SO4) ions make up the majority of barite. In the orthorhombic system, the mineral crystallizes and usually forms prismatic or tabular crystals. BaSO₄ is the chemical formula for barite. It is a non-metallic mineral with a specific gravity that ranges from 4.3 to 4.6, which is exceptionally high. Its high density is one of the main qualities that make barite so valuable in so many different industrial uses.

2.1. Physical Properties

- Color: Because to impurities, barite, which is normally colorless or white, can take on hues of yellow, brown, blue, or gray.

- Luster: The luster of it ranges from vitreous to pearly.

- Hardness: it is classified as somewhat soft on the Mohs scale, with a hardness of 3 to 3.5.

- Cleavage: The propensity of barite to create thin, translucent plates is partly due to its flawless cleavage in one direction.

3. Occurrence and Distribution

2.2. Crystal Habits Numerous shapes and sizes of barite crystals are possible, such as tabular, prismatic, fibrous, or even huge granular tendencies. Sandstone, limestone, and dolostone are the sedimentary rocks where the crystals most frequently develop.

It is found all over the world, with notable deposits in the US, Morocco, Turkey, China, India, and the United States. It usually occurs as a gangue mineral in metal ore veins, sedimentary deposits, and hydrothermal veins. Minerals like quartz, calcite, and fluorite are frequently linked to it.

3.1. Major Barite-Producing Regions

- China: It is the biggest producer, meeting about 40% of global demand.

- India: a major producer with large reserves in Rajasthan and Andhra Pradesh.

- United States: Nevada and Missouri contain significant deposits.

- Morocco: Well-known for its superior barite, especially in the Bou Azzer neighborhood.

4. Industrial Uses of Barite

Due to its special qualities, It is essential in a wide range of sectors. Although it has applications in other areas as well, its main use is in the oil and gas business.

4.1. Oil and Gas Industry It is primarily employed by the oil and gas sector, where it is incorporated into drilling muds as a weighing agent. Because barite has a high specific gravity, it can be used to stabilize the borehole and avoid blowouts by helping to regulate the pressure during drilling operations. In addition, the mud carries cuttings to the surface, cools and lubricates the drill bit, and seals the wellbore walls.

4.2. Chemical Industry Barium comes from barite and is used to make a number of different barium compounds. These compounds play a crucial role in the production of paints, plastics, rubber, ceramics, and glass, among other goods.

4.3. Medical and Imaging Applications It is used as a contrast agent in CT and X-ray imaging in the medical industry. Patients swallow barium sulfate to bring gastrointestinal tract features to light, enabling crisp views of the stomach, intestines, and esophagus.

4.4. Construction and Radiation Shielding High-density concrete, which acts as a radiation barrier in hospitals, power plants, and laboratories, is made in the construction sector using barite. Because of its density, barite is a highly effective substance for radiation absorption.

4.5. Automotive Industry In the automotive sector, barite is used as a filler material in paints, plastics, and brake linings. These items are more durable and effective because of its density and inertness.

5. Environmental and Safety Considerations

Despite being thought of as non-toxic in general, barite mining and processing can have an adverse effect on the environment. If barite extraction from the earth is not managed properly, it may cause habitat disruption, soil erosion, and water contamination. Furthermore, in order to protect the environment, oil and gas companies must dispose of drilling muds that include barite carefully.

6. Barite Manufacturer and Supplier

Leading barite manufacturers around the world ensure the supply of high-quality barium sulfate for diverse industrial applications, including drilling fluids, chemical production, and radiation shielding materials.

Barite suppliers play a crucial role in ensuring the steady availability of this vital mineral for industries ranging from oil and gas to construction and healthcare.

7. Barite Market Trends and Global Trade

The global demand for barite is closely linked to the oil and gas industry. Fluctuations in oil prices directly impact the demand for barite, as drilling activity increases or decreases in response to market conditions. The barite market is also influenced by the availability of high-quality deposits, trade regulations, and geopolitical factors.

7.1. Global Trade and Supply Chain The top three countries that export barite are Morocco, India, and China. The United States is the greatest importer, relying mainly on these countries to supply its local demand. Political unpredictability, trade constraints, and logistical difficulties can cause disruptions to global barite supply chains.

7.2. Future Market Outlook In the upcoming years, there will likely be a rise in the exploration and production of barite due to the oil and gas industry. Furthermore, the market will develop as a result of barite’s growing application in other sectors like healthcare and construction. The market will, however, also have to contend with issues including environmental concerns and the depletion of high-grade reserves.

Radiation shielding in construction and drilling fluids for the oil and gas sector are just two uses for the very important mineral barite. Its special qualities, especially its high specific gravity, make it an important resource for many different industries. Barite will continue to be essential to supplying the growing global demand for industrial and energy products. However, in order to guarantee that barite is accessible for future generations, sustainable mining methods and conscientious resource management will be necessary.

FAQs

Question 1: What is barite used for?

Answer: The primary source of barium for the production of compounds containing barium, such as reasonably pure precipitated barite, is barite. Precipitated barite finds application in paint, ink, paper, textile, and rubber as an extender and filler.

Question 2: Is barite toxic to humans?

Answer: Extended contact may irritate and cause redness. Consumption Pain in the stomach may result from ingestion. Not applicable if acute toxicity is unknown.

Question 3: How do you identify barite?

Answer: Cleavage/fracture: Barite exhibits three right-angled directions of basal cleavage. looks like a rose most of the time. Crystal Form: There are various crystal forms for barite. The first of several crystal forms is tabular, which resembles a narrow or tiny box.

Question 4: Where is barite found in India?

Answer: Ninety-eight percent of India’s baryte production comes from Andhra Pradesh. Only 24 of the 32 mines in India were located in the state of Andhra Pradesh. There are 21 mines in the Cuddapah district, 1 in Kham- mam district, and 2 in Prakasam district.