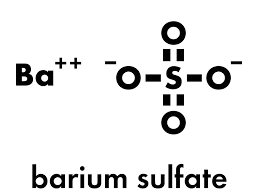

One of the most important industrial minerals in the world is barium sulfate (BaSO4), which occurs naturally as the mineral barite. Barite, well-known for its high density and capacity to obstruct gamma and X-rays, finds application in numerous fields that stimulate economic growth and innovation. This adaptable mineral is essential to current technologies and industrial processes, from oil and gas drilling to medical uses. Barite: The Industrial Mineral Driving Innovation examine the importance of barite, its characteristics, important uses, and how it is influencing many sectors going forward.

1. What is Barite?

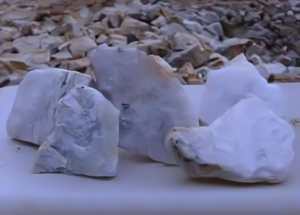

Barium sulfate is the source of barite, another name for the mineral. Usually white or colorless, it can have a variety of hues, including blue, gray, brown, yellow, and so on, depending on the impurities. Large, tabular, granular, or fibrous shapes are typical for barite crystals.Its exceptional density—which comes from the Greek word “barys,” which means heavy—is one of its defining characteristics.

Barite is perfect for applications that need weight without bulk because of its high specific gravity, which usually ranges from 4.2 to 4.5.

2. Key Properties of Barite

Due to its special qualities, barite is a necessary mineral in many different industrial areas.

- High Density: One of the most important characteristics of barite, especially for drilling purposes, is its weight.

- Non-Toxic: Barite is utilized in products that come into touch with people, like paints and medical devices, because it is non-toxic.

- X-Ray Absorption: Because barite is non-toxic, it is used in items that come into contact with people, such as paints and medical devices.

3. Industrial Applications of Barite

Because of its adaptability, barite can be employed in a variety of industries, fostering innovation and growth.

a) Oil and Gas Drilling

Barite is mostly employed in the oil and gas sector, where it is a weighing ingredient in drilling fluids. Drilling fluid with a higher density when made using barite-based muds helps keep the wellbore pressure stable and prevent blowouts. The heavy mineral also makes sure that drilling waste is effectively transported to the surface. Because of this, barite is essential to the energy industry, particularly when exploring for deeper gas and oil reservoirs.

b) Medical Imaging

Because barite can absorb both gamma and X-rays, it is perfect for medical imaging. It is utilized in barium sulfate solutions, sometimes referred to as “barium meals,” which patients consume in order to highlight specific digestive system organs on X-rays. This demonstrates how important it is for non-invasive medical diagnostics.

c) Paints, Coatings, and Plastics

In the paint business, barite serves as an extender and filler, giving coatings weight and durability while cutting expenses. Barite is a great pigment extender, especially in white and brightly colored paints, due to its tiny particle size and white tint. Similar to this, barite is added to plastic composites in the plastics industry to improve mechanical characteristics and density.

d) Radiation Shielding

In places where radiation protection is required, like hospitals, nuclear power plants, and industrial sites, barite is employed as a shielding material. Because of its capacity to obstruct dangerous radiation, it is the perfect addition to concrete for building barriers and walls that shield people from exposure to gamma and X-ray radiation.

e) Rubber and Paper Industries

Additionally, the paper and rubber industries employ barite as a filler. In paper, it promotes smoothness and whiteness; in rubber, it increases strength and durability. These sectors profit from barite’s low cost and the distinctive qualities it gives their goods.

4. Barite’s Role in Innovation and Sustainability

Beyond its conventional applications, bentonite is a mineral that fosters sustainability and creativity. Barite is now essential in the following sectors as industries change and the need for sophisticated materials rises:

a) Advancements in Drilling Technology

Deeper and more intricate oil and gas wells are a result of the world’s increasing energy demand, necessitating the use of high-performance drilling fluids. Reducing operating costs and minimizing environmental impact are two benefits of using barite in the development of more ecologically friendly drilling methods.

b) Green Technologies

Barite is found more and more in green technologies, such as renewable energy storage systems, to build efficient, long-lasting materials because of its high density and inert nature. The use of barite in carbon capture and storage systems is also under study because it has the potential to significantly reduce greenhouse gas emissions from industrial sites.

c) Environmental Protection

In industries where environmental pollution is an issue, bentonite appears in products that require non-reactive, non-toxic materials. As a result, it is currently found in eco-friendly paints and coatings as well as medical devices that need to be safe.

5. Barite Production and Supply

India, along with China and the United States, is one of the world’s top producers of barite. A competitive global market has resulted from the demand for high-quality barite, with suppliers and manufacturers providing a range of grades to suit different industry needs. Indian barite is in high demand worldwide, especially in the oil and gas industry, because to its reputation for purity and quality.

SNDB Manufacturer and suppliers

Supplying Solutions: Meeting Diverse Client Needs

Apart from manufacturing and exporting, SNDB is a proficient provider that offers customized solutions to fulfill the distinct requirements of its customers. Because of its adaptable and responsive design, the company’s supply chain enables it to effectively handle high volumes and fluctuating demands.

Within the ever-changing landscape of international trade and industry, SNDB is a leading manufacturer, exporter, and supplier of superior goods. SNDB has been a reliable partner for customers worldwide thanks to its dedication to quality and innovation. This article examines SNDB’s competitive advantages and how it performs exceptionally well in its core competencies.

SNDB’s standing as a top supplier, manufacturer, and exporter is evidence of its persistent dedication to innovation, quality, and client satisfaction. In order to stay competitive in the market, SNDB combines client-centric supply, worldwide export strategy, and sophisticated manufacturing techniques. SNDB is committed to providing quality and making a positive impact on the global industry environment as it advances.

FAQs

Question 1: What are the primary uses of mineral barite in consumer goods?

The main applications for mineral barite are as fillers in rubber, plastics, and paints. It adds to the overall quality and lifetime of these products by improving their texture, performance, and durability.

Question 2: What investment opportunities exist in the Mineral Barite Market?

The emergence of new applications and the rising demand for barite have resulted in a wealth of investment prospects. In addition to investigating new market niches, investors are concentrating on mining and processing technologies that improve productivity and product quality.

Question 3: How is the Mineral Barite Market expected to grow in the coming years?

The market for mineral barite is expected to rise significantly as a result of rising industrial activity, expanding applications for barite, and technical developments. By the end of the decade, significant values are anticipated in the market.

Question 4: What recent innovations are shaping the Mineral Barite Market?

New processing methods, improved barite-based products, and mining technology developments are examples of recent innovations. With these advancements, the production process will be more efficient, the product will be of higher quality, and barite will find more uses.