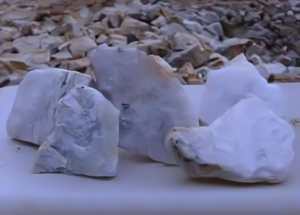

Barite, a naturally occurring mineral made of barium sulfate (BaSO₄), is becoming more and more well-known as a flexible filler in the production of plastics. SNDB, a business dedicated to providing top-notch materials that enhance industrial applications, is one of the top producers, suppliers, and exporters of premium BaSO₄. Because of their proficiency in processing and providing barite, they have established themselves as a reliable partner for businesses looking to enhance plastics’ qualities.

Barite: A Game-Changer in Plastic Properties

Because of its special blend of chemical and physical properties, it is a necessary addition in the plastics sector. It has several advantages that improve the functionality and affordability of plastic items.

Key Advantages of Barite in Plastics

- Improved Strength and Durability

By strengthening their structural integrity, it makes plastic products more resilient to deterioration. Because of its high density and strength, it produces durable final products that can withstand demanding applications. - Enhanced Flexibility

it guarantees that polymers maintain their flexibility while increasing strength, which is crucial for items like films, packaging, and resilient components. - Cost Reduction

Barite guarantees that polymers maintain their flexibility while increasing strength, which is crucial for items like films, packaging, and resilient components. - Thermal Stability

Its capacity to tolerate high temperatures makes it perfect for plastic applications exposed to heat, providing dimensional stability and preventing deformation. - Improved Surface Finish

Barite-filled plastics frequently have smoother, more polished surfaces, which improves the final products’ tactile and visual appeal.

SNDB: Leaders in Barite Supply and Export

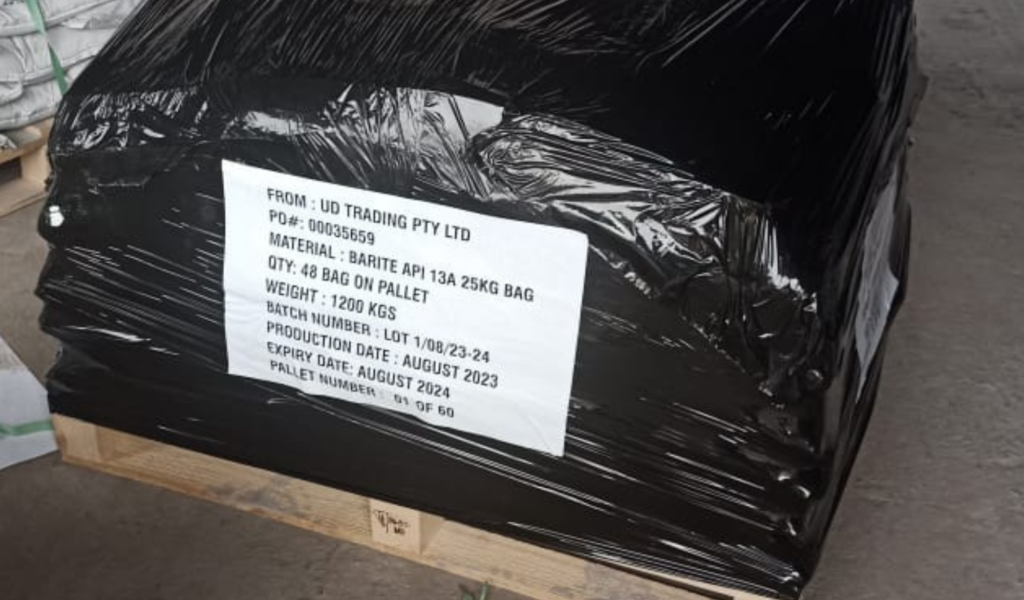

SNDB is a manufacturer, supplier, and exporter that specializes in providing high-purity BaSO₄ that is suited for the plastics sector. They provide barite with the ideal particle size and consistency for plastic applications because to their cutting-edge equipment, which guarantees precision processing.

Why Choose SNDB?

- High-Quality Standards

To ensure that BaSO₄ satisfies industry standards and performs well in all applications, SNDB uses strict quality control procedures. - Global Reach

Being a well-known exporter, SNDB provides BaSO₄ to customers worldwide, guaranteeing prompt delivery and affordable prices for global markets. - Custom Solutions

Recognizing the different needs of plastic manufacturers, SNDB offers bespoke barite grades, enabling clients to achieve specified product qualities.

Applications of Barite-Filed Plastics

- Automotive Components

Automotive parts that are lightweight and long-lasting are made using barite-filled polymers, which improve safety and fuel economy. - Packaging Materials

It increases plastic films’ tensile strength and durability, which qualifies them for use in heavy-duty packaging. - Construction Plastics

Barite-filled plastics are prized in the construction industry for their durability and dependability due to their resilience to severe environmental conditions. - Consumer Goods

Baso4-infused plastics improve the quality and affordability of commonplace products, including toys, containers, and home goods.

Because of its dedication to quality barite production, supply, and export, SNDB is a reliable partner for businesses all over the world. Manufacturers may produce plastics that are tougher, more flexible, and more affordable while meeting a variety of application needs by including BaSO₄ into the process.

With SNDB, there are countless opportunities to enhance the qualities of plastic by using barite.

FAQs{ frequently asked question }

Question 1. What is the role of barite in improving plastic properties?

Answer: In order to improve plastics’ strength, resilience, flexibility, and thermal stability,BaSO₄ is added as a filler. Additionally, it lowers manufacturing costs and enhances the surface polish of plastic products.

Question 2. Why should manufacturers choose SNDB for barite supply?

Answer: In order to improve plastics’ strength, resilience, flexibility, and thermal stability, barite is added as a filler. Additionally, it lowers manufacturing costs and enhances the surface polish of plastic products.

Question 3. What are the key applications of barite-filled plastics? Answer: When increased strength, durability, and cost-effectiveness are needed, BaSO4-filled polymers are utilized in consumer items, building products, packaging materials, and automotive components.